- Home

- About Us

- Products & Services

- Modular OT/ICU/ER

- Medical Gas Pipeline System

- Integrated Sterilizer with Shredder (ISS)

- Central Sterile Supply Department

- OT Table and OT Lights

- OT Equipments

- Hospital Furniture and Equipment

- Burn Ward and Equipment

- Nurse Call System

- Pneumatic Tube System

- Hospital Consultancy & Designing on Turnkey Basis

- Smart Bin System

- Pneumatic Waste/Laundry Collection System

- Oxygen Generation System

- Electric Track Vehicle

- Automated Pharmacy Dispensing System

- Quality Control

- Download Catalogues

- Contact

Med freshe Private Limited > Modular OT/ICU/ER

AN INTRODUCTION

Modular OT / ICU / Emergency Room / OT Integration (MOT)

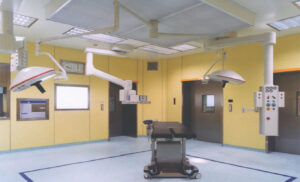

Historically, the term "operating theatre" referred to a non-sterile, tiered theatre or amphitheater in which students and other spectators could watch surgeons perform surgery. Contemporary operating rooms are devoid of a theatre setting, making the term "operating theatre" a misnomer.

The most complex and challenging area of hospital construction is the operating department. Modular Operation Theatre (MOT) offers the advantage of speedy construction combined with design, future expansion and development in surgical technique whilst simultaneously providing a structure of the highest quality and standards.

MOT, where most integrated functions are always required, such as hygiene must be preserved with safety facilities, equipment and device must be maintained any times. Furthermore, the working environment for medical staff such as doctors and nurses must be considered from the view point of human engineering.

Med Freshe MOT have been satisfying the hygienic needs of a hospital while consisting of a ceiling and wall panels, doors and is capable of incorporating not only electrical equipment, medical gas pipeline system (MGPS) recording and archiving systems and lighting gears but all the necessary functions and equipments at need. In addition, it has a high accessibility with high workability and ample functions, which is provided for the introduction of a new facility in the future.

The modular operation theatre (MOT) integrated approach to the construction and co-ordination of operating Theatre.

Features

-

A continuous flow of highly filtered ‘bacteria-free’ air is reticulated under positive pressure into the operating field and air contaminants generated during surgery are removed from the site.

-

Easy to clean steam cleaned, electro metric (ideal for high humidity areas).

-

Vapour permeability (allows substrate moisture to escape) protects against growth of bacteria, mould and yeasts.

-

Moisture resistance, freeze / thaw resistance.

-

High standard of asepsis.

-

Seamless, Economic.

-

Future Expansion.

-

Optimal working conditions for the surgical and supporting team.

-

Maximum standard of safety for patient and staff from environmental, anesthetic & radiological equipment and peri & post operative hazards.

-

Flexibility in the design of OT to ensure optimum utilization of OT and staff time.

Modular Operation Theatre (MOT)

Operation Theatre (OT) is that specialized facility of the hospital where life saving or life improving procedures are carried out on the human body by invasive (Operative) methods under strict aseptic conditions in a controlled environment by specially trained personnel to promote healing and cure with maximum safety, comfort and economy.

Modular ICU

Modular intensive care units are custom-built and designed; that means you'll never be forced to 'make do' with what you have. In addition, these spaces can be quickly and easily modified to offer a truly reliable and effective treatment area.

Modular Emergency Room

Being the most traumatic department of hospital it very important that it should be designed in a modular manner with propper planing of aesthetics and infection control.

Main Systems / Equipment

-

Plenum Unit (Laminar Air Flow)

-

Wall and Ceiling panelling system

-

OT Light with Camera, Monitor and Recorder

-

OT Pendants (Anesthetist and Surgeon)

-

Hermetically Sealed Door

-

O.T. Control Panel

-

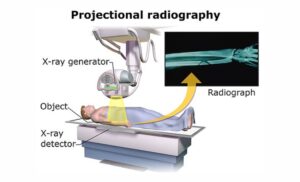

X-ray / Pac Viewer

-

Pressure Relief Damper

-

Medical Gas Lines Installations

-

Storage Unit

-

Scrub Station

-

O.T. Table

-

Anti-Static Flooring

-

Writing Board

-

View Window

-

Hatch Box

-

Equipment Storage Unit

-

Pressure Stabilizer

-

Peripheral Lighting, Electrical and Clean Room Luminaries

Wall & Ceiling

The modular operation room will be a free standing structure. Constructed room composite free standing. These panels are produced from various materials like:

-

HPL • SS-304 Panel • SS-316 Panel

-

Toughened Glass Panel • EGP • SMS

All the four corners have return air duct outlets and grill for the same made of steel duly powder coated with the colour choice to suit the hospital. Distance between the walls and panels to be around 100 mm(or as per designed), it has full support to provide straight by using clamps near the columns. Additional space can be utilized for making storage area/ hatch box (pass box/cabinet). Anti bacterial paint may used so that its anti microbial features remain active through out the life of the product. The tolerate harsh cleaning and chemical agents dry film thickness of finished surface to be 200 microns or medical grade gaskets.

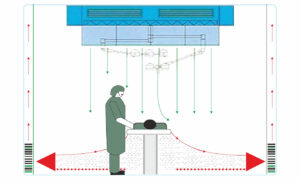

Plenum Unit (Laminar Air Flow)

The ceilings consist of a plenum box supplied with conditioned air from the central system via HEPA filters mounted on the inlet to the supply ceiling.

All HEPA filters and housings are factory tested and certified in accordance with DIN:1946 and DIN:4799. All ceilings incorporate supports to secure them to the main structural frame of the modular operating theatre, or structural slab.

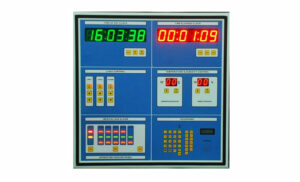

Control Panel

All the controls for the MOT are to be provided on a micro processor controller based electronic control panel mounted in the theatre wall. Control panel to meet the electrical safety codes for high and low voltage systems. The control panel to be user friendly and case of operating and maintenance purpose. The fascia to be made with superior quality UV resistance membrane with sterilization feature. Membrane type and touch screen are available.

Hermetically Sealed Door

The use of hermetically sealed sliding doors is to maintain satirically and the correct air pressure in the room, which requires less valuable space than hinged doors. The doors are operated manually and/or automatically with microprocessor based electronic automation system. The door frames are made out of high quality anodized aluminum extrusion and the door panel made out of compact laminated board that can withstand high abrasions. The controllers are capable of either being operated by elbow switches/ foot Switches, radar switch (touch less sensor). All doors able to be operated manually easily in the event of failure power supply or the automation unit.

Energy Bridge - MOT ICU Emergency

We first implemented the idea of enclosing the operating field with an energy supply bridge – and immediately met with a very broad positive response. Typically, the our energy supply bridge is immediately noticed because of its exceptionally compact design. The exceptionally compact design, giving it a unique elegance. Moreover, the flexibility of our equipment carriers underlines just how ergonomic and easy-to-use our energy bridges are.Yet despite the extremely compact form, our energy supply bridge is exceptionally robust, as evidenced by the excentrally arranged monitor consoles and arms. Our energy supply bridge service side is deliberately set away from the aseptic operating field – a solution maintaining a distance between the laminar field and the bridge, systematically preventing non-sterile equipment from projecting into the sterile laminar field.

Pendants MOT ICU Emergency

In an Operating Theatre, the two most important personnel are the anaesthetists and the surgeon. With their handy uses next to them, they form a group of specialized people who strive to heal and save lives. A well designed working environment is much appreciated by them. This includes proper ventilation, advance surgical tools and also positioning of the supply system. The anaesthetist is always positioned behind the patient's head and the surgeon towards the patient's leg.

Pendants provide:

Medical gases supply to equipment | Electrical power supply | Data points | Shelves for some equipment | Drawers for accessories | Support arms for mounting monitors, pumps, equipment | Mounting of Medical Devices & others

Pressure Relief Dampers

A modular OT or ICU should always have a positive pressure as compared to the outside environment. As more and more Sterile air is being inducted into the room, a suitably sized Air Pressure Releaser is required to be installed in the room. This SS fabricated product with adjustable blades is an integral part of Ultra Clean Rooms.

Pass / Hatch Box

A Hatch is provided in each Operation Theatre to remove waste materials from the Operation Theatre to Dirty linen Area just adjacent to Operation Theatre. Hatch Box is equipped with two doors and the door is operated electronically and designed in such a way that only one door will be opened at one time.

A UV light is so installed that it is kept ‘ON’ while both the doors are closed, this UV light shall automatically be turned ‘OFF’ in case the door open. Indicators on both sides of the OT indicates the open/close status of both sides. Manual & sliding door options are available.

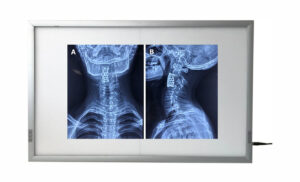

X-ray / Pac Viewer

X-Ray / Pac Viewer is low on power consumption, provides a homogeneous imaging effect a shadow free design that dissipates very low energy and heat and is suitable to be used for long hours.

-

Provides flicker-free viewing effects.

-

Also available for the other areas of hospitals.

-

Brightness control through electronics system consisting of dimming ballast and dimming PCB.

-

These can have different sizes and configurations such as single, double, quad plated and in customizable sizes.

OT Integration

Integration in operation theater (OT) usually refers to systems integration, which means functionally connecting the OT environment. It includes integration of patient information system, audio, video, surgical lights and room lights, building automation (HVAC), medical equipment, telemedicine, video conferencing, etc.

Surgical Scrub Station

The unit is made of high quality stainless steel (304 / 316).

Tailor made to suit the site available. The unit is compatible with all the regular and standard plumbing. The unit has sensor controlled water flow based on advanced microprocessor system. The unit has user selectable time-out control for rinse timing. The unit has thermostatic control of water temperature.

The unit has irrigation facility to allow washing of instruments, tubes, endoscopes etc. The body is designed to eliminate backsplash, overflow and stagnation. The unit has option of manual actuated water supply by or foot operated taps. Soap operation is available by both a hand pump as well as hand free controls. The unit has jet irrigation facility to allow washing of instruments, tubes, endoscopes etc.

Available in Single User, Two User & Three Users Models. Floor Mounted or Wall Mounted Options.

Equipment Storage Unit

The storage cabinets brings ease and simplicity to any healthcare space with a diverse line of storage cabinets. From supply cabinets to desk consoles, these storage solutions are fully customizable and can adapt to a variety of clinical environments. Eliminate clutter and gain valuable floor space while enjoying convenient access to the supplies required for patient care.

Operation Theater Table

Various types of OT tables are available including manual, hydraulic, fully automatic and having options of various positions, specialities and it's attachments .

Automatic Curtain Window

Aluminium Powder Coated windows designed for operation theater as per guidelines, These windows are customized as per customer request.

-

Frame: Aluminium Powder Coated

-

Blinds customization

-

Glass Size : As per requirement.

Surgical Light

Surgical light plays a vital role in operation theatre. Operating lights are designed to meet all surgical illumination requirements of operating theatres. New generation LED technology helps the surgeons to operate and view the surgery area clearly. LED lights can be adapted in any size of operating theatres including large hybrid types with variety of models & combinations.

Manoeuverability

The Lux surgical lights have both A and B rotation points extremely close to the centre, allowing exceptional, near ball-joint mobility. With fingertip light manipulation. Lux lamps can be positioned in the appropriate angle.

Advantages of Grouping of Ots

-

Flexibility In Use

-

Easy Expansion In

-

Future

-

Better Training & Staff Utilization

-

Better & Maintenance

-

Better Utilization of Equipment’s & Instruments

-

Flexibility In OT Allocation

-

Minimize Infection

-

Better Cleaning & Asepesis